Chain slings are made from high-strength alloy steel made specifically for the lifting industry. They have numerous configurations and end fittings. Standard slings are available in two grades of steel: Grade 80 and Grade 100. Chain slings are the most rugged slings available. They are resistant to both abrasion and cutting and may be used at temperatures up to 400°F (204˚C) without reducing capacity rating. Grade 100 slings are 25% stronger per chain diameter than Grade 80. All chain slings are manufactured to the customer’s specifications and in accordance with industry standards.

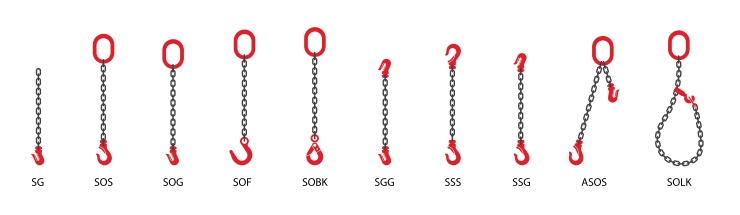

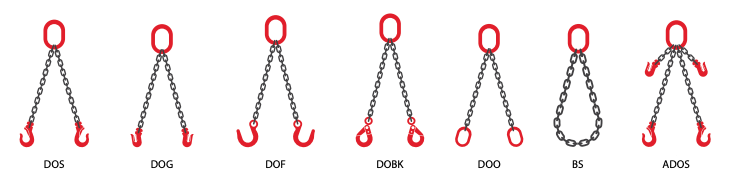

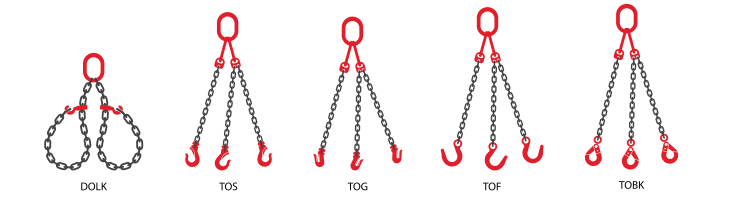

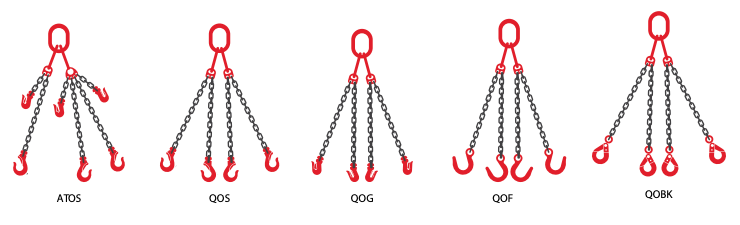

Chain Sling Type Naming Code

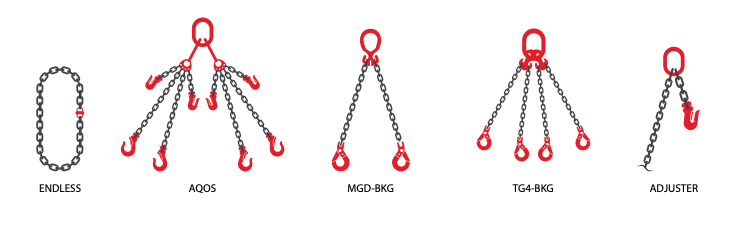

Basic chain sling configurations are often described using a code. Naming conventions have many exceptions and may vary among manufactures.

- First letter often designates the number of legs or branches:

S Single leg with one branch

D Double leg with two branches

T Triple leg with three branches

Q Quadruple leg sling with four branches - Second letter normally designates the fitting at the top of the sling:

O Oblong-shaped master link

S Sling hook

G Grab hook

B Basket with oblong master sling - Third letter or group of letters normally designates the fitting at the bottom of each branch. A few of the many possibilities are listed below:

S Sling hook

G Grab hook

LK Sliding choker

BK Self Locking

F Foundry hook

If A precedes the group of letters, then a device to adjust the length has been added. Adjusters can be either of two styles, Type A or Type B. Examples are shown below.

Example: ADOS describes an Adjustable, Double Leg Sling with Oblong master link on top and a Sling hook at the bottom of each leg or branch.